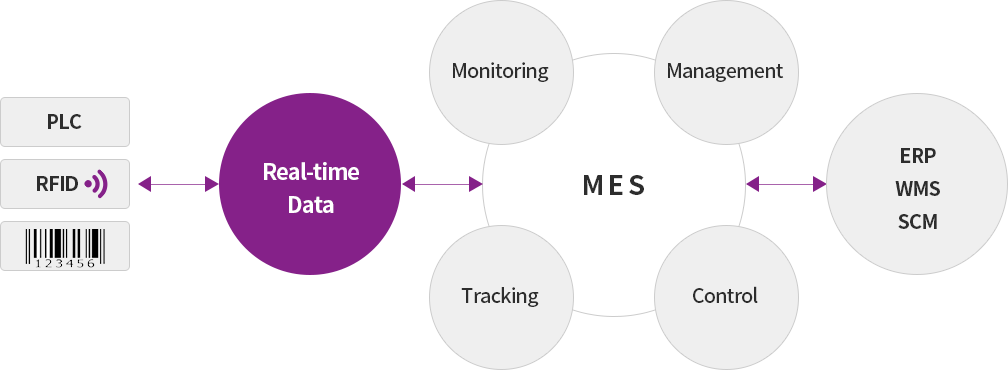

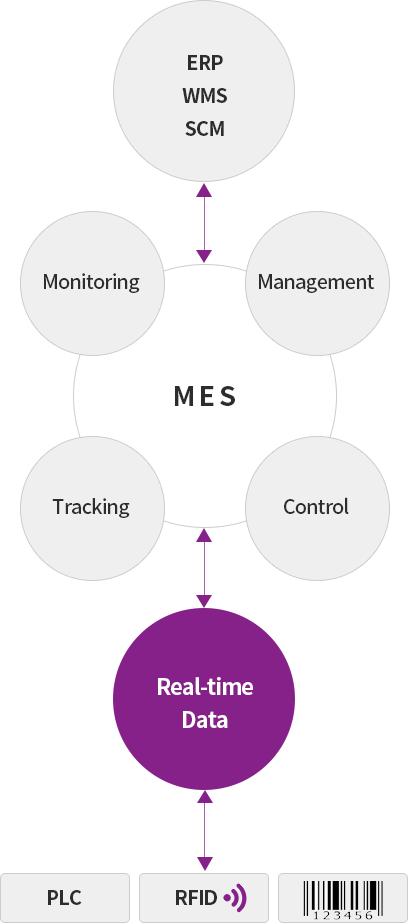

RF Engine's RFID Solution

1. Automatic identification and tracking

Automatically identify and track parts, raw materials, and products on the manufacturing line through RFID tags

▶ Identify the location and status of products in real time and manage inventory and production flow

2. Increase worker productivity

Workers can easily identify and track products using RFID tags.

▶ Less time spent in work processes, more productivity

3. Automated process control

Automatically detect which product or part has reached which work stage at each stage of the production line using RFID

▶ Automated process control is possible

4. Quality Management

Using RFID, product quality information is stored in tags and the production process is monitored in real time.

▶ Immediate action upon detection of defective products and abnormal conditions.

5. Resource management and optimization

Real-time monitoring of inventory levels using RFID technology to prevent understocking or overstocking.

▶ Reduce inventory costs and optimize production planning

6. Production data collection and analysis

Collect and analyze data obtained from RFID tags to monitor and improve production line performance.

▶ Identify bottlenecks or areas for improvement in the production process

7. Flexibility and scalability

RFID solutions are a relatively easy technology to deploy and scale.

▶ Respond flexibly to changes in production lines or work processes